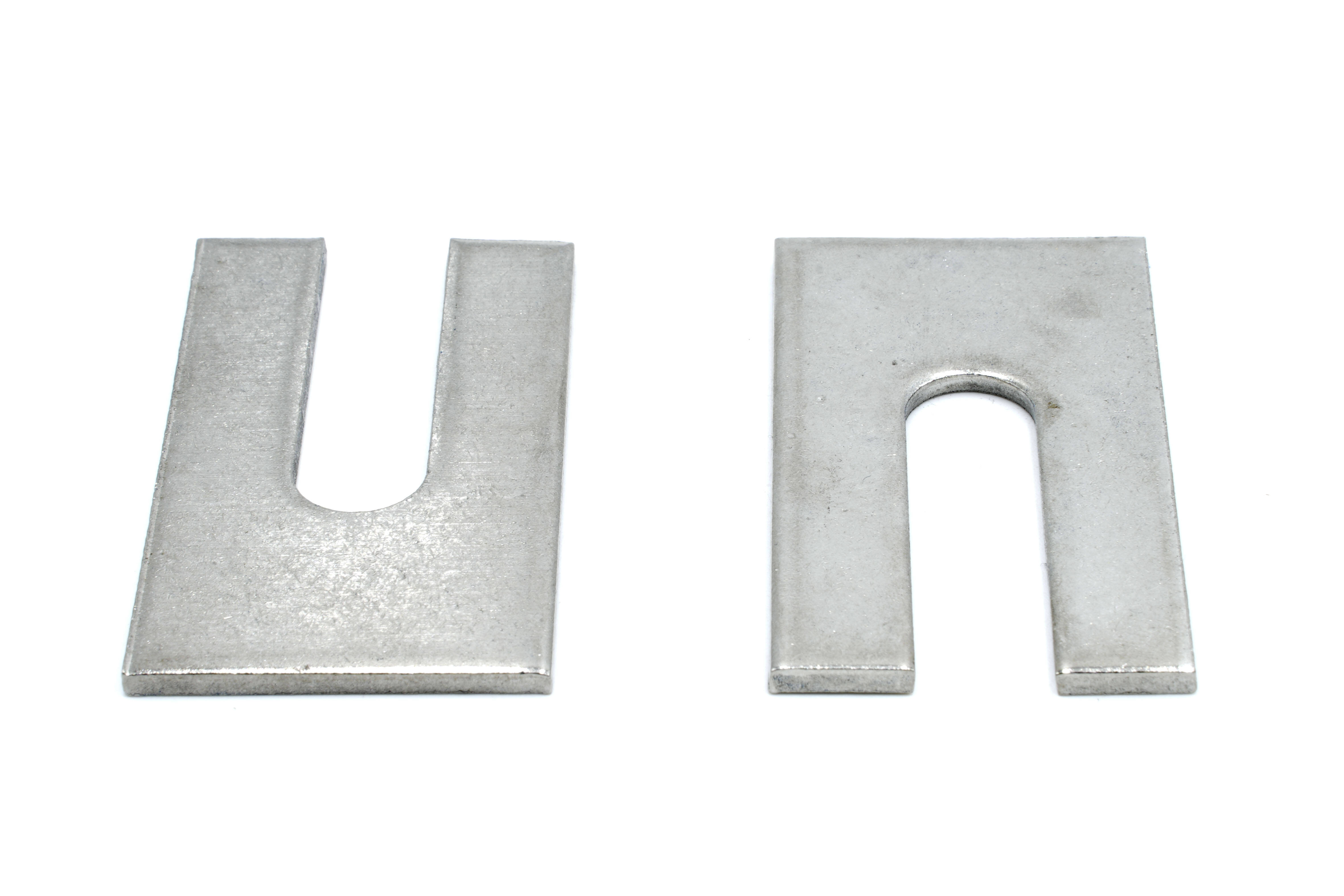

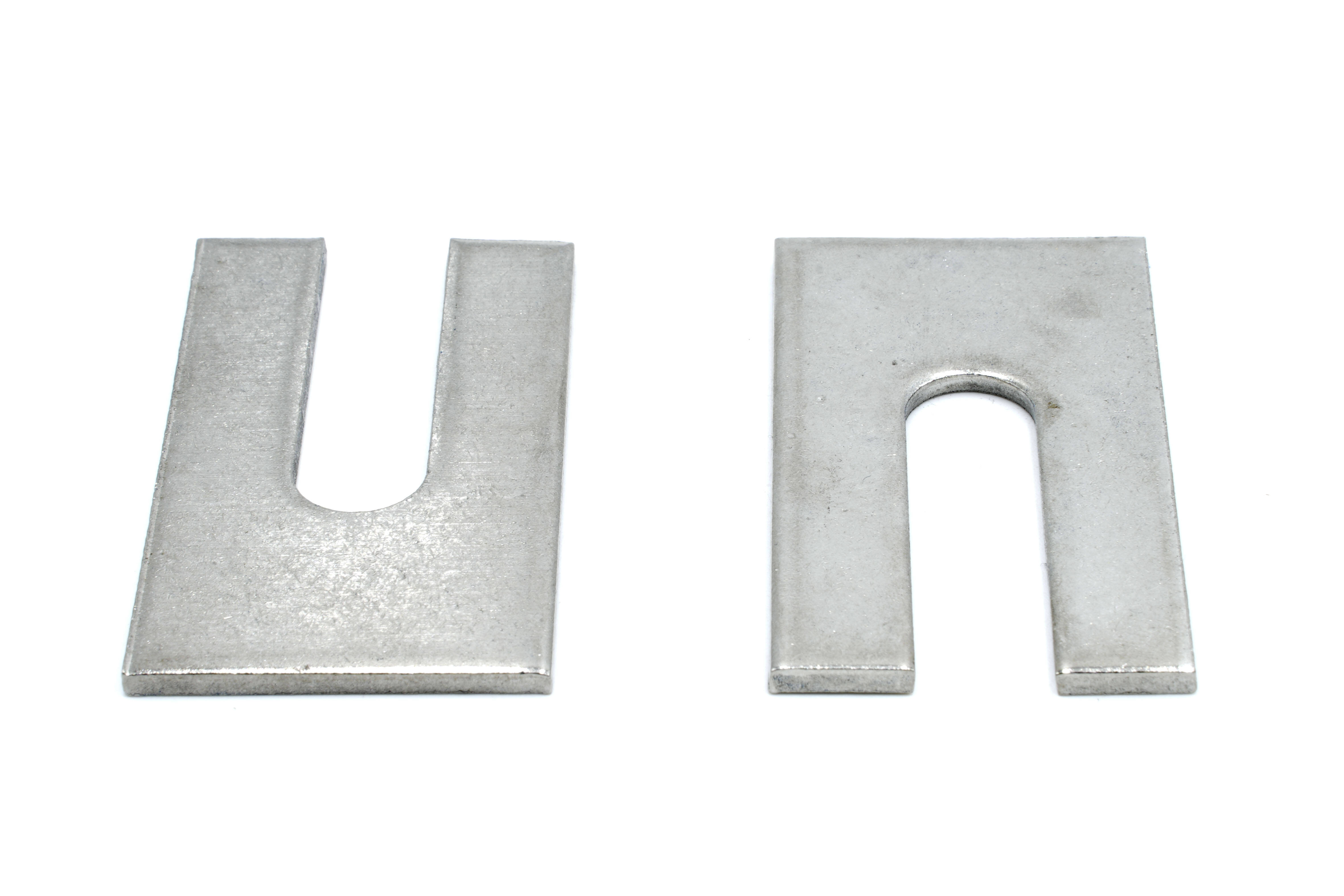

Washers are thin, flat discs with a hole in the center, used in conjunction with bolts, screws, and nuts to distribute the load of the fastener, prevent loosening, and protect the surface being fastened. They come in various types, including flat washers, spring washers, and lock washers, each serving a specific purpose. Flat washers are the most common type, providing a uniform load distribution and preventing damage to the surface by spreading the pressure of the nut or bolt head over a larger area. Spring washers, also known as Belleville washers, are conical in shape and provide a preload to the fastener, compensating for loosening due to vibration or thermal expansion. Lock washers, on the other hand, have a split or toothed design that digs into the mating surface, preventing the nut or bolt from rotating and loosening over time. Washers are widely used in industries such as automotive, construction, and machinery, where secure and reliable fastening is essential. For example, in automotive manufacturing, washers are used to secure engine components, suspension systems, and body panels, ensuring stability and durability under regular use. In construction, they are commonly used in structural steel frameworks, bridge building, and roofing systems, where load distribution and protection against corrosion are critical. For professionals seeking reliable and versatile fastening solutions, washers offer a cost-effective and efficient choice. For specific pricing or custom requirements, please contact us for further details.